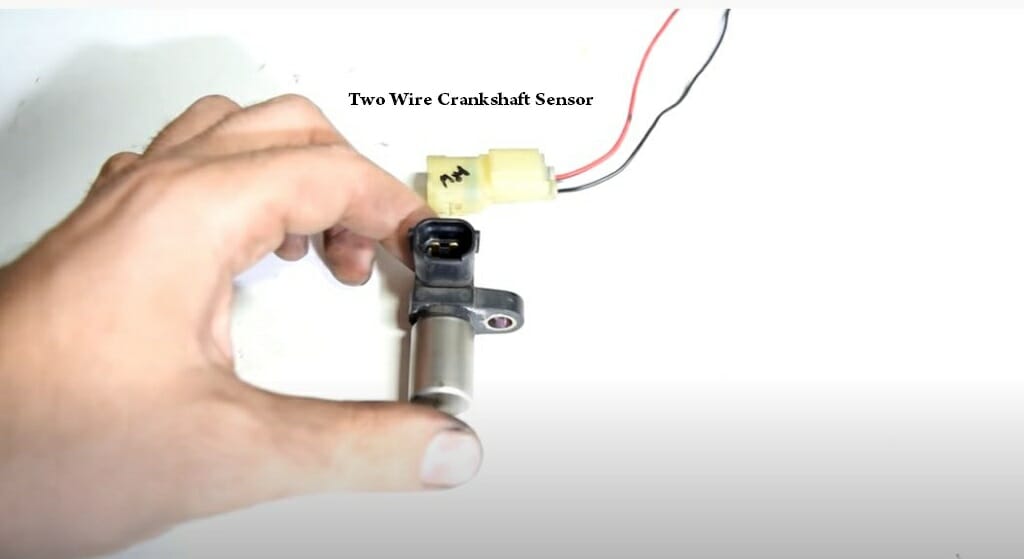

Crank Position Sensor Resistance Test . If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. here is how to test a crankshaft position sensor with or without a code: It should display an engine speed. Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. how to test crankshaft position sensors without any guess work using. to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage, and ac voltage or frequency. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. If your check engine light is on,. in this episode i show how to test a two wire magnetic crankshaft. in this video i show you how i test crankshaft position sensor.

from toolsweek.com

here is how to test a crankshaft position sensor with or without a code: If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. in this video i show you how i test crankshaft position sensor. to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage, and ac voltage or frequency. It should display an engine speed. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. If your check engine light is on,. in this episode i show how to test a two wire magnetic crankshaft. how to test crankshaft position sensors without any guess work using. Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position.

How Many Ohms Should a Crank Sensor Have?

Crank Position Sensor Resistance Test Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. how to test crankshaft position sensors without any guess work using. If your check engine light is on,. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage, and ac voltage or frequency. If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. here is how to test a crankshaft position sensor with or without a code: in this episode i show how to test a two wire magnetic crankshaft. in this video i show you how i test crankshaft position sensor. It should display an engine speed.

From knitterlybits.blogspot.com

How To Test Crankshaft Position Sensor With Multimeter Electronic Crank Position Sensor Resistance Test in this video i show you how i test crankshaft position sensor. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage, and ac voltage or frequency. here is how to test a. Crank Position Sensor Resistance Test.

From garageemautl6.z14.web.core.windows.net

How To Test Crank Position Sensor Crank Position Sensor Resistance Test in this episode i show how to test a two wire magnetic crankshaft. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. If your check engine light is on,. how to test crankshaft position sensors without any guess work using. If you have a diagnostic tool capable. Crank Position Sensor Resistance Test.

From carfromjapan.com

How To Test Camshaft And Crankshaft Position Sensors Crank Position Sensor Resistance Test It should display an engine speed. If your check engine light is on,. Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. here is how to test a crankshaft position sensor with or without a code: to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage,. Crank Position Sensor Resistance Test.

From axleaddict.com

How to Test a Crankshaft Position Sensor Using a Multimeter AxleAddict Crank Position Sensor Resistance Test in this video i show you how i test crankshaft position sensor. If your check engine light is on,. here is how to test a crankshaft position sensor with or without a code: Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. how to test crankshaft position sensors without. Crank Position Sensor Resistance Test.

From www.youtube.com

Advanced Crankshaft Position Sensor Testing P0335 YouTube Crank Position Sensor Resistance Test in this video i show you how i test crankshaft position sensor. here is how to test a crankshaft position sensor with or without a code: It should display an engine speed. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. If you have a diagnostic tool. Crank Position Sensor Resistance Test.

From www.youtube.com

how to test denso crankshaft position sensor good or bad alza Crank Position Sensor Resistance Test in this video i show you how i test crankshaft position sensor. Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. to test the crank sensor, you’ll need a multimeter capable. Crank Position Sensor Resistance Test.

From www.youtube.com

Bench Test a 3 Wire Crankshaft Position Sensor YouTube Crank Position Sensor Resistance Test If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. in this video i show you how i test crankshaft position sensor. It should display an engine speed. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. in. Crank Position Sensor Resistance Test.

From exooldwyw.blob.core.windows.net

How To Test Miata Crank Position Sensor at Lorie White blog Crank Position Sensor Resistance Test If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. in this episode i show how to test a two wire magnetic crankshaft. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. in this video i show you. Crank Position Sensor Resistance Test.

From mechanicsujudovb.z14.web.core.windows.net

Crankshaft Position Sensor Testing Crank Position Sensor Resistance Test to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage, and ac voltage or frequency. in this video i show you how i test crankshaft position sensor. If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. Now that safety considerations are covered, let's discuss. Crank Position Sensor Resistance Test.

From axleaddict.com

How to Test a Crankshaft Position Sensor Using a Multimeter AxleAddict Crank Position Sensor Resistance Test If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. in this episode i show how to test a two wire magnetic crankshaft. Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. here is how to test a crankshaft position sensor. Crank Position Sensor Resistance Test.

From www.youtube.com

DSM Crankshaft Position Sensor CPS Testing YouTube Crank Position Sensor Resistance Test If your check engine light is on,. Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage, and ac. Crank Position Sensor Resistance Test.

From xiaoyanzong.blogspot.com

Test Crank Sensor Resistance Sensor Center site Crank Position Sensor Resistance Test how to test crankshaft position sensors without any guess work using. Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. If your check engine light is on,. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. It should display an. Crank Position Sensor Resistance Test.

From workshopvlierhoutgps.z13.web.core.windows.net

How To Test A Crankshaft Position Sensor With Multimeter Crank Position Sensor Resistance Test If your check engine light is on,. in this episode i show how to test a two wire magnetic crankshaft. Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage, and ac voltage or frequency. in. Crank Position Sensor Resistance Test.

From electronicshacks.com

How to Test 3 Wire Crank Sensor with a Multimeter? ElectronicsHacks Crank Position Sensor Resistance Test Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. If your check engine light is on,. to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage, and. Crank Position Sensor Resistance Test.

From axleaddict.com

How to Test a Crankshaft Position Sensor Using a Multimeter AxleAddict Crank Position Sensor Resistance Test If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. It should display an engine speed. to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage, and ac voltage or frequency. in this episode i show how to test a two wire magnetic crankshaft. If. Crank Position Sensor Resistance Test.

From id.hutomosungkar.com

19+ How To Test The Crankshaft Position Sensor New Hutomo Crank Position Sensor Resistance Test If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. You’ll also need to identify the location of the crank sensor, which varies depending on the vehicle make and model. how to test crankshaft position sensors without any guess work using. Now that safety considerations are covered, let's discuss the. Crank Position Sensor Resistance Test.

From toolsweek.com

How Many Ohms Should a Crank Sensor Have? Crank Position Sensor Resistance Test to test the crank sensor, you’ll need a multimeter capable of testing continuity, voltage, and ac voltage or frequency. how to test crankshaft position sensors without any guess work using. in this episode i show how to test a two wire magnetic crankshaft. here is how to test a crankshaft position sensor with or without a. Crank Position Sensor Resistance Test.

From schematiclistdrescher.z19.web.core.windows.net

Testing A 2 Wire Crank Sensor Crank Position Sensor Resistance Test Now that safety considerations are covered, let's discuss the essential tools required for testing the crankshaft position. how to test crankshaft position sensors without any guess work using. If your check engine light is on,. If you have a diagnostic tool capable of reading rpms, attach it to the sensor and crank the engine. You’ll also need to identify. Crank Position Sensor Resistance Test.